Types of Levers: First, Second & Third Order Examples

In lever, there are three different ways of arranging effort, load, and fulcrum. Therefore, depending on the relative positions of the fulcrum, the load, and the effort there are three different types of levers. We also call these three different types or three orders of levers.

These three types or orders of levers are:

- Class I or first-order levers

- Class II or second-order levers

- Class III or third-order levers.

Types of Levers

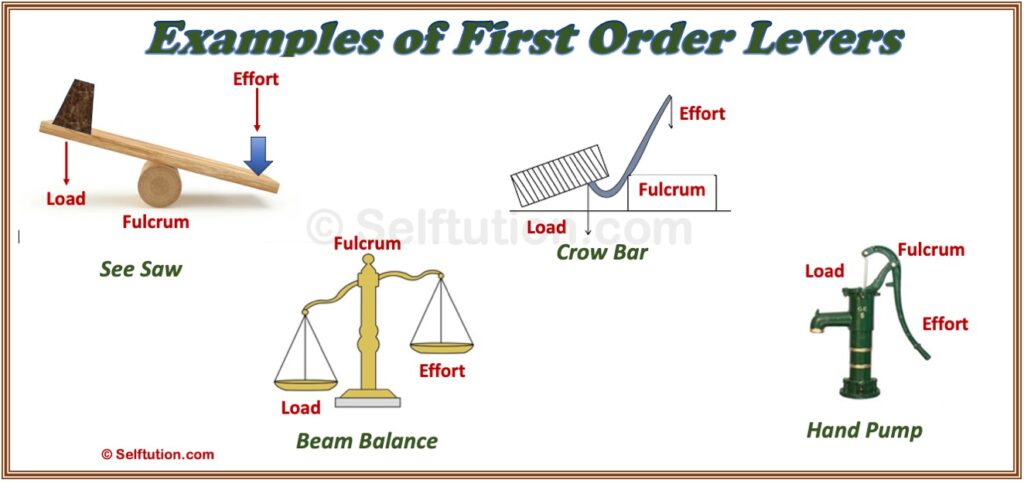

Class-I or First-Order Lever

In class I or first-order liver, the fulcrum is in between the load and the effort.

In the lever of the first order, the effort arm may be equal to or less than or more than the load arm.

We require a small effort to move the load if the effort arm is more than the load arm. However, if the effort arm is less than the load arm, a large effort is required to move a load. Therefore, based on the length of the load arm and the effort arm, the mechanical advantage can be more than 1, equal to 1, or less than 1. Examples of first-order levers are a see-saw, a crowbar, a claw hammer, a hand pump, a beam balance, etc. Two such levers which share the same fulcrum form a pair of scissors or pliers.

Four examples of a first-order lever – see-saw, beam balance, crowbar, and hand pump

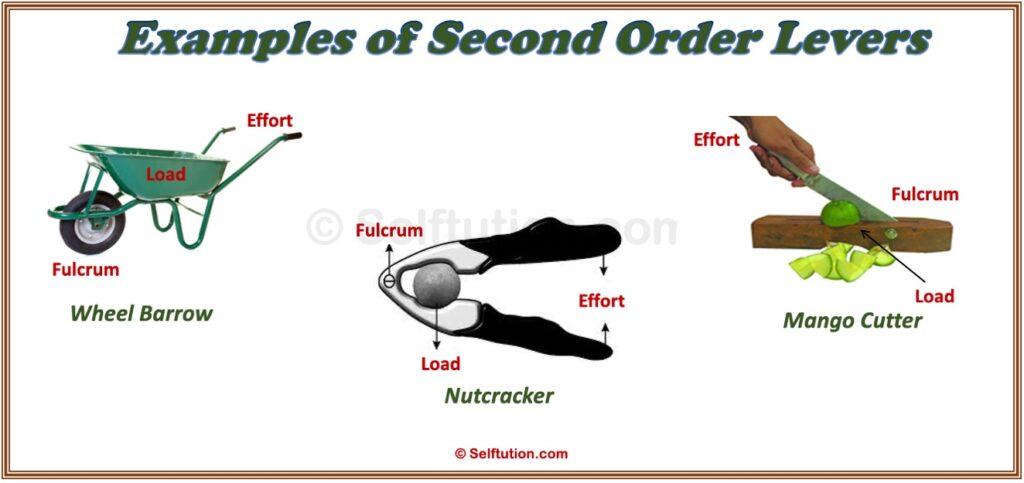

Class-II or Second-Order Lever

In class II or second-order lever, the load is in between the fulcrum and the effort.

In the lever of the second order, the load arm is always smaller than the effort arm. Thus, always less effort is required to move a heavy load. Consequently, the mechanical advantage is always more than 1 as the effort arm is longer than the load arm. We also call the second-order lever an effort or force multiplier lever. Nutcrackers, wheelbarrows, mango cutters, etc., are some examples of second-order levers.

Three examples of a second-order lever – wheelbarrow, nutcracker, and mango cutter

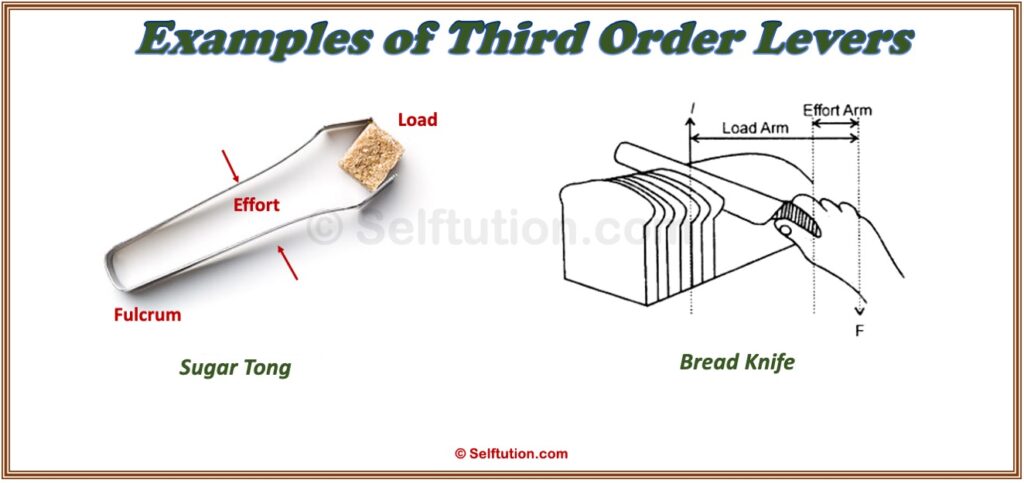

Class-III or Third-Order Lever

In class III or third-order lever, the effort is in between the fulcrum and the load.

In the lever of third-order, the effort arm is always smaller than the load arm. Therefore, we have to apply more effort to lift a lighter load. Thus, the mechanical advantage is always less than 1 as the effort arm is shorter than the load arm. We also call the third-order lever a speed multiplier lever as the load moves through a larger distance as compared to the effort. Some examples of third-order levers are sugar tongs, bread knives, fire tongs, etc.

Two examples of a third-order lever – sugar tong and bread knife

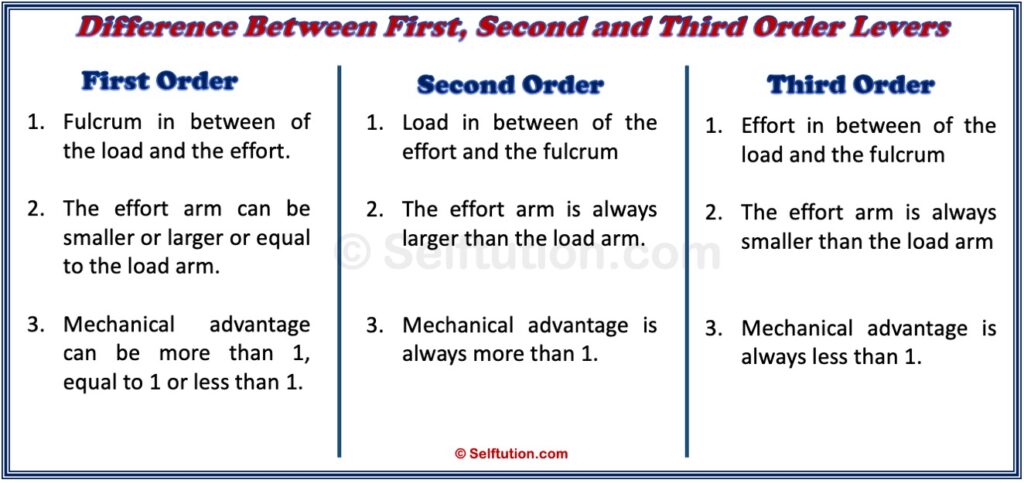

Differences between first, second, and third order

There are three important differences between first-order, second-order, and third-order levers. These are:

- The most important difference between the three types of levers is the relative position of fulcrum, load, and effort with respect to each other. In the first-order lever, the fulcrum is in between the load and the effort arm, whereas in the second-order lever, the load is in between the fulcrum and the effort arm. Subsequently, in the third-order lever, the effort is in between the fulcrum and the load arm.

- In the first-order lever, the effort arm can be smaller, equal to, or larger than the load arm. Whereas, in the second-order lever, the effort arm is always larger than the load arm, and in the third-order lever, the effort arm is always smaller than the load arm.

- The mechanical advantage of the first-order lever is greater than, equal to, or less than 1. Whereas, in the second-order lever, the mechanical advantage is always greater than 1 and in the third-order levers, the mechanical advantage is always less than 1.

Difference between first, second, third order levers

Please go through the below video from NGScience to learn more about various types of levers. Courtesy NGScience