Simple Machines: Types, Related Terms and Examples

Simple machines make work easier by reducing effort, changing force direction, or increasing speed. They are everywhere, from household tools to playground equipment.

Many people think machines are complex devices with engines or electricity. However, even basic tools like hammers, spoons, and bottle openers are simple machines.

These machines help us lift heavy objects, cut materials, or fasten things together. They require no fuel or electricity, relying only on mechanical advantage.

In daily life, we use simple machines without realizing it. A seesaw, a pair of scissors, or a screwdriver all function based on simple principles.

Understanding these machines helps us appreciate their role in making tasks easier. By learning their types and functions, we can see their importance in technology and engineering.

Let’s explore different types of simple machines, essential terms related to them, and examples of how they are used in everyday life.

Simple Machines

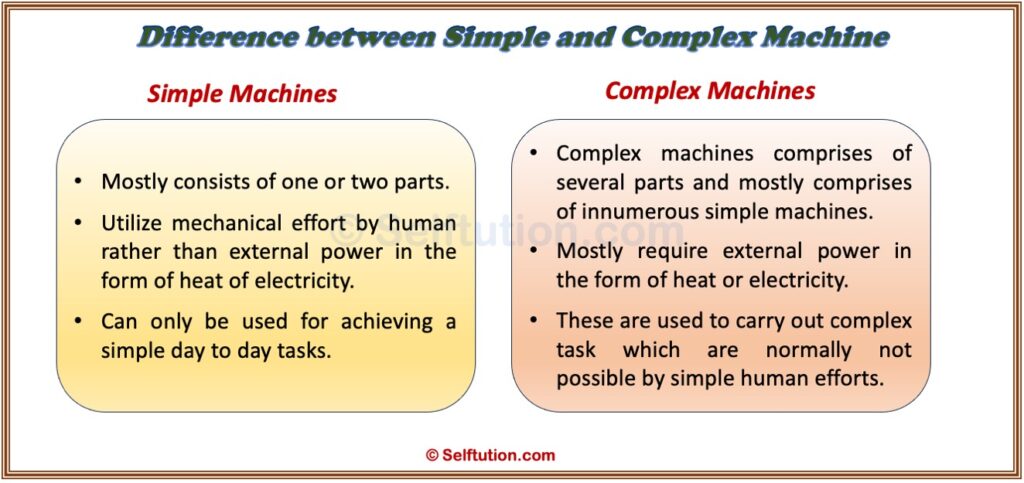

Difference between simple and complex machines

Characteristics of Simple Machines

- They consist of one or two parts pivoted at some points to achieve a mechanical advantage.

- Simple machines do not utilize power in the form of heat or electricity to operate.

- They help humans to achieve more work by putting in less effort.

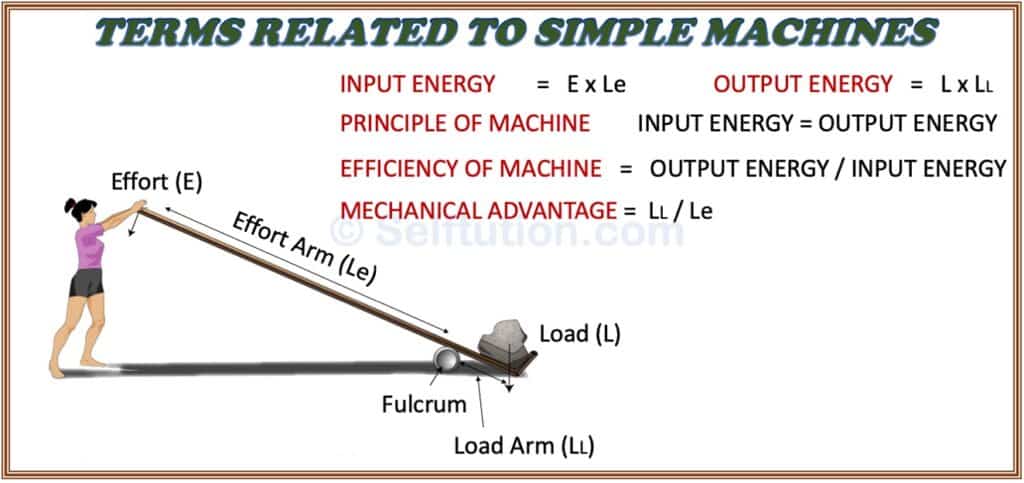

Terms related to Simple Machines

- Effort: The force applied to a machine to do some mechanical work.

- Load: The weight moved or the resistance overcome by a machine in doing mechanical work.

- Fulcrum: A fixed point or an axle around which a machine turns in doing mechanical work.

- Effort arm: The perpendicular distance between the effort point and the fulcrum of the machine.

- Load arm: The perpendicular distance between the load point and the fulcrum of the machine.

- Input energy: The energy supplied to the machine for doing mechanical work.

- Output energy or Mechanical work: It is the work done or the energy produced by a machine.

- Principle of Machine: For an ideal machine, the output energy or work is equal to the input energy.

- Efficiency of Machine: This is the ratio between the output energy of the machine to the input energy.

- Mechanical advantage: The ratio between the load (resistance overcome) moved by the machine and the effort applied.

Terms related to simple machines are explained with the help of the Class-I lever.

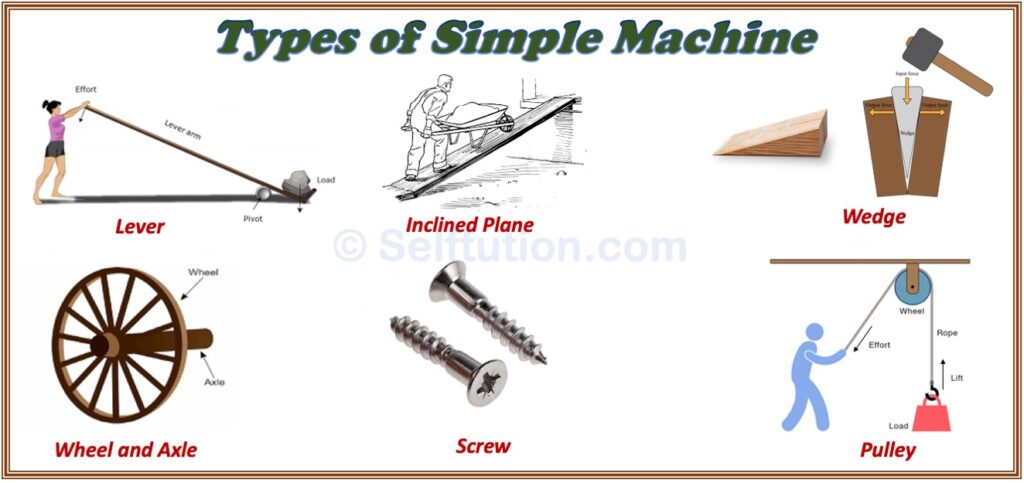

Types of Simple Machines with Examples

There are six types of simple machines we use in our daily lives. They are:

- Lever,

- Inclined Plane,

- Wedge,

- Screw,

- The wheel and axle, and

- Pulley.

Six types of Simple Machines – a lever, an inclined plane, a wedge, a wheel and axle, a screw, and a pulley

It is important to note here that every mechanical device, even the complicated giant earth mover, is made from these six different types of simple machines.

1. LEVER

A lever is a simple rigid rod that is free to move or rotate about a fixed point called the fulcrum. The object that is to be moved is called the load or resistance, whereas the force applied to the lever to overcome the load is called effort. Depending upon the relative position of the fulcrum, load, and effort, levers are classified into three types:

- Class I levers, or the first-order levers: the position of the fulcrum is between the load and the effort. For example, beam balance, seesaw, crowbar, pair of scissors, pliers, claw hammer, etc.

- Class II levers, or the second-order levers: the position of the load is between the fulcrum and the effort. For example, a nutcracker, a wheelbarrow, a mango cutter, a bottle opener, etc.

- Class III levers, or the third-order levers: the position of the effort is between the fulcrum and the load. For example, forceps, sugar tongs, a bread knife, etc.

2. INCLINED PLANE

An inclined plane is a sloping flat surface along which a load can be easily pushed or pulled. It does not look like a machine at all! Inclined planes are simple machines that help raise the load above the ground to a certain height by applying less effort. Some examples of inclined planes are stairs, hill roads, etc. The steeper the slope of the inclined plane more effort will be required to raise the load. Therefore, winding roads on hills have a gentle slope, so that vehicles can easily climb to the top.

3. WEDGE

A wedge is a simple machine with two inclined planes put together, forming a sharp edge. It helps us to tear apart solid objects. By using a wedge, we can easily tear apart a piece of wood, which otherwise would not be possible. For pushing apart a solid object or wood, we place the sharp end of the wedge on it. Subsequently, hammering the same from the wider end helps the sharp end to penetrate the wood, which tears it apart. Some examples of wedges are an ax, nails, needles, knives, etc.

4. SCREW

A screw is a simple machine that looks like a nail with grooves on its circular curved surface. In other words, a screw is an inclined plane wound around a rod. It consists of a rod with a thread. One end of the rod is narrow or pointed which is called the tip of the screw, whereas the other end is flat which is called the head of the screw. The head consists of a narrow slit which helps to turn the screw with the help of a screwdriver. The threads act like an inclined plane. When the screw makes one complete rotation, the rod advances a distance equal to the space between the two consecutive threads.

It takes less force to insert a screw into wood than to insert a nail. This is because the screw makes it move round and round as it goes in, traveling a longer distance than a nail. Further, because of the grooves a screw holds the wood more firmly than a nail. A jack used for lifting heavy vehicles is also a type of screw.

5. WHEEL AND AXLE

A wheel and axle (or rod) is another form of simple machine. We all know the importance of a wheel. A wheel is a circular object capable of rotating along its axis. So, when a wheel rotates, the rod attached to its axis also rotates. We use wheels like a roller to reduce friction. The wheel, when used with an axle, acts as a simple machine.

An axle behaves like a wheel. Therefore, a wheel and axle consists of two wheels of different diameters attached. Some examples of wheels and axles are the steering wheel of motor cars, bicycle pedals, door knobs, screwdrivers, etc. In every type of wheel and axle, we apply effort on the bigger wheels and load on the rod or axle. Therefore, we mostly use the wheel and axle to induce rotational motion in heavy objects by applying less effort.

6. PULLEY

A pulley is a flat circular disc with a groove in its edge and a rope or a chain passing through the groove. It is capable of rotating around the fixed point passing through its central axis, called the axle. We use a pulley in workshops and factories to lift heavy loads and to change the direction of the force applied. While using a pulley, we attach a load at one end of the rope and apply effort to the other end of the rope in a downward direction. Consequently, the load moves upward. Pulleys are normally made of metal, but in villages, we see people drawing water from a well with the help of wooden pulleys.

You may also like…... Types of Chemical Reactions in Chemistry